Iris Lunar Rover: Battery Bracket

Iris is the first ever student-built lunar rover: contracted to land on the moon in early 2022. Check out a video here. I designed and manufactured its lightweight 3D printed battery bracket, made of Antero 800NA. This key component presses the batteries against the contact springs, and secures the battery assembly to the radiator, providing power to the robot while maintaining electrical and thermal isolation from other components.

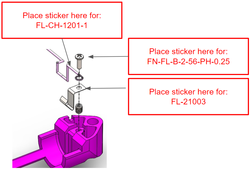

I used the geometry of the batteries and ring terminals to create a bracket in Solidworks that held those components snugly. I then used FEA to optimize the shape for low mass, and verify the part's strength. I selected Antero 800NA since it is the highest strength material that can be used in Fused Deposition Modeling, has a high heat deflection temperature, and is low outgassing, which are critical features of a space grade part. Next, I used Stratasys's Insight software to manually add air gaps and align raster angles of support material layer by layer, which reduced polymer adhesion between the support and model material. Finally, I perfected the printer's configuration to manufacture the most precise brackets possible.

|  |  |

|---|---|---|

|  |  |

|  |  |

|  |